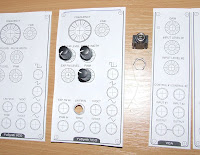

The alignment of the sockets seems correct:

The alignment of the sockets seems correct: YuSynth LFOs:

YuSynth LFOs:

Now, Mr. Braska has gone... but today, i've received the parts, which are needed to continue the modular project. A bigger toroidal transformer, PIC for the Midibox CV, 110 jack sockets, a lot of jack plugs, knobs, resistors, caps, etc...

![]() 0

megjegyzés

Date:

17:42

0

megjegyzés

Date:

17:42

A few weeks ago, i've made a picture set of the panel making process, so here are the details.

Wash the panel with water, and dry it... The height distance between the untouched surface, and the etched one is about 0.2-0.3 mm. I think its ideal for painting, i don't need to etch it down to 0.4-0.5 like the instructables article suggest it.

After 24-48 hours of drying (depending on paint), scrub off the excess paint with a rough surfaced sponge. If everything is done correctly this can't damage the paint on the lower surface too much, but takes the laser toner layer off with the spray paint on it.

Drill the panel, then clear the surface, and cover with clear coat. This eliminates the small scratches.

Enjoy your panel, and show it to me! :)

![]() 0

megjegyzés

Date:

09:28

Címkék:

diy,

etching,

front panel,

hydrogen peroxide

0

megjegyzés

Date:

09:28

Címkék:

diy,

etching,

front panel,

hydrogen peroxide

The last few weeks wasn't really productive (it's summer...), but i've started wiring up the frontpanels. It's not an easy job for me...

Here are the YuSynth ADSRs, and the YuSynth sample&hold + noise, and the YuSynth ringmod.

![]() 0

megjegyzés

Date:

22:59

Címkék:

adsr,

analog synthesizer,

modular synthesizer,

yusynth

0

megjegyzés

Date:

22:59

Címkék:

adsr,

analog synthesizer,

modular synthesizer,

yusynth

This picture shows the current state of my project. These are the PCBs of my 'basic' modular (except for the Midibox). I've realised, that I must redesign the mixer for my own needs, so i've started an Eagle project for this module, based on Yves's design. This is a simple goal for my nonexistent sdiy knowledge.

![]() 0

megjegyzés

Date:

21:19

Címkék:

modular synthesizer,

pcb,

yusynth

0

megjegyzés

Date:

21:19

Címkék:

modular synthesizer,

pcb,

yusynth

Today was a productive day! The case was clear coated, and I need to wait 24 hours before I can continue the work. I've drilled the front panels, made 8mm holes for the pots. The jacks need 12mm ones, which I can't drill at home, so next week I will drill these at my workplace.

I've drilled the front panels, made 8mm holes for the pots. The jacks need 12mm ones, which I can't drill at home, so next week I will drill these at my workplace. If I'll finish all of the drilling, I'll have 9 panels, with these modules:

If I'll finish all of the drilling, I'll have 9 panels, with these modules:

- 2 VCOs

- 2 VCFs

- 2 ADSRs

- 2 LFOs

- 4 VCAs

- Dual ringmodulator

- Noise + Sample and hold

![]() 0

megjegyzés

Date:

17:50

0

megjegyzés

Date:

17:50

The case is almost finished! It only needs to be clear coated to protect the surfaces. It's very lame, made by me. :) The wood parts was taken from old furniture, shelves, and garbage. This case can hold 8x2 modules, totally 16 of my nonstandard sized modules. More pictures with the front panels coming soon! :)

![]() 0

megjegyzés

Date:

10:11

0

megjegyzés

Date:

10:11

I've found a great article on instructables.com: How to etch aluminium panel with reusable acid. This method uses the same cheap acid, which is able to etch copper pcbs. This process is easy, and cheap, so here are the results of my test:

![]() 0

megjegyzés

Date:

20:12

0

megjegyzés

Date:

20:12

I'm designing my own panel layouts with the great free and opensource vector graphics program: Inkscape (available for Windows, Mac, and Linux!). This program creates SVG files, and with the clone function it's easy to draw consistent panel elements. For example, if I change the size of the original element, all of the clones resizing too.

I'm tested the layout, and it seems to everything is at usable distance. The graphics needs to be refined, but the dimensions are fine.

![]() 0

megjegyzés

Date:

20:26

Címkék:

diy,

front panel,

prototype

0

megjegyzés

Date:

20:26

Címkék:

diy,

front panel,

prototype

Hoooraay, two of the +15V supply rails are built up, and functioning! Each of them is capable of cca 500 mA, which is quite good for me. The red leds shows the 2 regulated output, and the yellow ones indicating the unregulated. Next time, of course I will finish the -15V side.

![]() 3

megjegyzés

Date:

20:31

Címkék:

psu,

synth,

testing

3

megjegyzés

Date:

20:31

Címkék:

psu,

synth,

testing

We have done with the PSU PCB, and drilling is completed. My father helps me to complete this project, he has the experience for this. The PSU parameters are: +/-15V, 2x1A, with two 7815 and two 7915 voltage regulators.

We need to mount the aluminum heatsinks, the transformer, and then begin to solder.

![]() 2

megjegyzés

Date:

20:43

2

megjegyzés

Date:

20:43